In today’s fast paced economy, the speed at which a product moves from concept to market can determine its success or failure. Businesses are no longer competing solely on innovation or price. They are competing on time. This is where rapid prototyping changes the game. By enabling faster design iterations and earlier market testing, it allows companies to bring products to market faster than ever before.

For any manufacturing company looking to maintain a competitive edge, adopting rapid prototyping is not just an option. It is a necessity.

From Idea to Prototype in Record Time

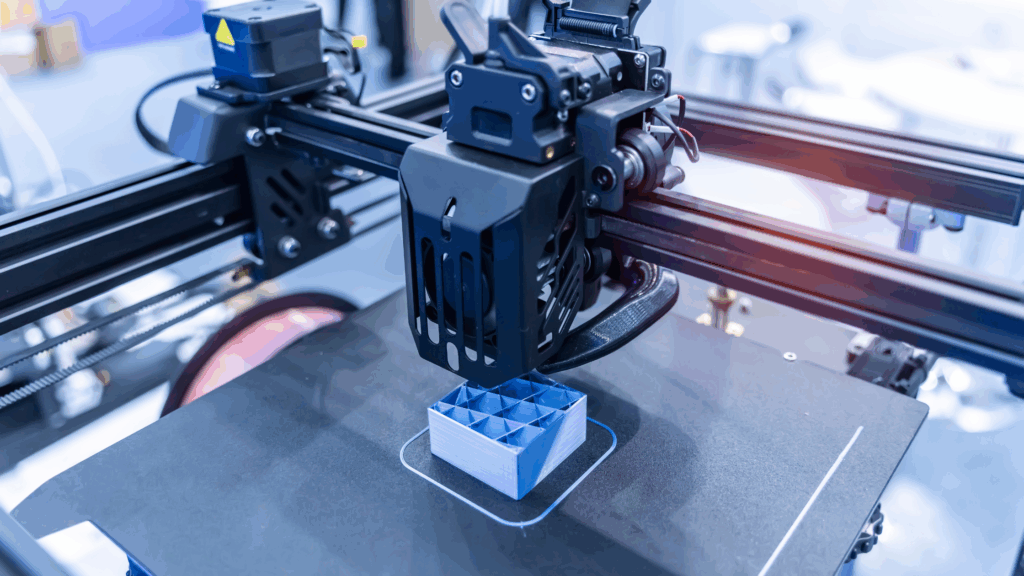

The traditional product development process can be slow, involving months of design adjustments before a physical model is ever produced. Rapid prototyping compresses that timeline dramatically. Using advanced 3D printing, CNC machining, and die casting techniques, a manufacturing company can create accurate, functional prototypes in days rather than weeks or months.

This speed allows design teams to experiment with different concepts quickly, identify flaws earlier, and make improvements without delaying the overall project. In industries where trends shift rapidly, this can be the difference between leading the market and playing catch up.

Reducing Costs and Risks Through Early Testing

One of the most powerful benefits of rapid prototyping is risk reduction. By producing a tangible version of a product early in the development cycle, businesses can test its functionality, usability, and durability before committing to large scale production. This helps avoid costly manufacturing errors and ensures that the final product meets both design and performance expectations.

For products that require die casting, rapid prototyping also enables the creation of molds and components faster. This not only saves time but also ensures that the production process is optimized before significant investment is made.

Faster Feedback, Better Products

Another advantage of rapid prototyping is its ability to speed up feedback loops. Instead of relying solely on digital renderings, companies can put a physical model into the hands of customers, stakeholders, and testers. Real world interaction often reveals issues or opportunities that computer models cannot fully capture.

This process enables businesses to make data driven design improvements and ensures that the final product resonates with the target market. For a manufacturing company, this means fewer redesigns, shorter lead times, and more successful product launches.

Winning with Speed and Precision

In modern markets, speed is not just an advantage. It is a survival strategy. Rapid prototyping equips businesses with the ability to innovate quickly, reduce risks, and respond to market demands in real time. When combined with advanced manufacturing methods like die casting, it creates a seamless path from idea to market ready product.

For any manufacturing company committed to staying ahead, embracing rapid prototyping is the smart move. The faster you can test, refine, and produce, the faster you can win in today’s competitive landscape.