Our Services

Anyone can create simple. At Rapid Product Creations complexity is our specialty. Offering manufacturing expertise across our portfolio of processes.

Services

Explore Our Offerings

CNC Machining

Versatile manufacturing process providing the ability to machine the simplest to the most complex geometries

Die Casting

Traditional well-proven manufacturing technology producing complex geometries in non-ferrous metals

Sheet Metal

A fundamental strategy in traditionally manufactured metal parts consisting of primarily bending, folding, and cutting

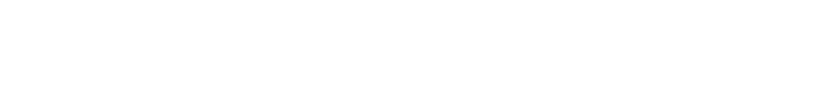

3D Printing

Additive manufacturing provides the ability to produce geometries that are otherwise impossible without using traditional processes

Injection Mold Tooling

Producing cores and cavities in exceptionally short lead times enabling clients to produce prototype and production injection molded components

Urethane Casting

Providing the ability to produce large geometries that emulate color, texture, & material characteristics of injection molded parts without expensive tooling

3 & 5 Axis CNC Machining

Plastics and Metals, Prototype or Production

Specializing in the most complex geometries and delivering results in exceptionally short lead times, while meeting desired specifications, is why our customers continue to come back to us time and time again.

If you are looking for 1 part or 1,000 parts, prototype or production, RPC is the solution for you.

Plastic Injection Tooling & Molding

Up to 1250 Ton Press

Rapid Product Creations has over 25 years of experience manufacturing injection mold tools, producing high quality injection molded parts. Producing tooling to meet the need of the product life. If you are looking for 1,000 or 10,000 parts, require soft Aluminum prototype tools or fully automated H13 production tools, we have the right solution for you. Short tooling lead times and repeatable quality each and every time.

RTV Cast Urethane

Vacuum Casting

At Rapid Product Creations we still believe in one of the oldest technologies for producing plastic parts. A prototype or a low volume production process that emulates the material characteristics, color, and surface finish of injection molding. Well suited for large parts with a low volume requirement, without the cost of expensive tooling.

3D Printing / Rapid Prototyping

Rapid Product Creations offers the three most widely used 3D printing processes available.

SLS (Selective Laser Sintering) – A powdered nylon support-free process used for prototype and production parts.

SLA (Stereolithography) – A liquid-based photosensitive process, primarily used for prototype projects.

FDM (Fused Deposition Modeling) – An extrusion process utilizing a wide range of materials for prototype and production parts.

Die Casting

Die casting has been around since 1838 with the first patent granted in 1849. It’s an old and well proven technology. Commonly used to produce metal parts in mostly non-ferrous metals, specifically zinc, copper, aluminum, and magnesium. With lead times as low as 3 weeks for the tooling and initial samples, RPC can offer this service with the support of our established HPDC suppliers.

Sheet Metal

At Rapid Product Creations we know that sheet metal is one of the fundamental forms used in metalworking. Everyday objects are fabricated from sheet metal in every industry imaginable. Thicknesses can vary significantly; from “foil” thickness up to 6 mm. Straight forward geometries can be supplied in a matter of days, with more complex design requiring tooling prior to part manufacture.

FAQ

General Question

Deciding on the correct process for your part is critical to receiving exactly what you ordered. Lead time requirement is a large factor when deciding what process direction to choose.

We prefer Step files, but we also accept IGES, and STL files for 3D Printing.

Injection Molding is a manufacturing process for producing parts in larger volume. It is most typically used in mass-production processes where the same part is being created thousands or even millions of times in succession.